Blog Post Title

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

23 Maine Street, Richmond , CA 94804

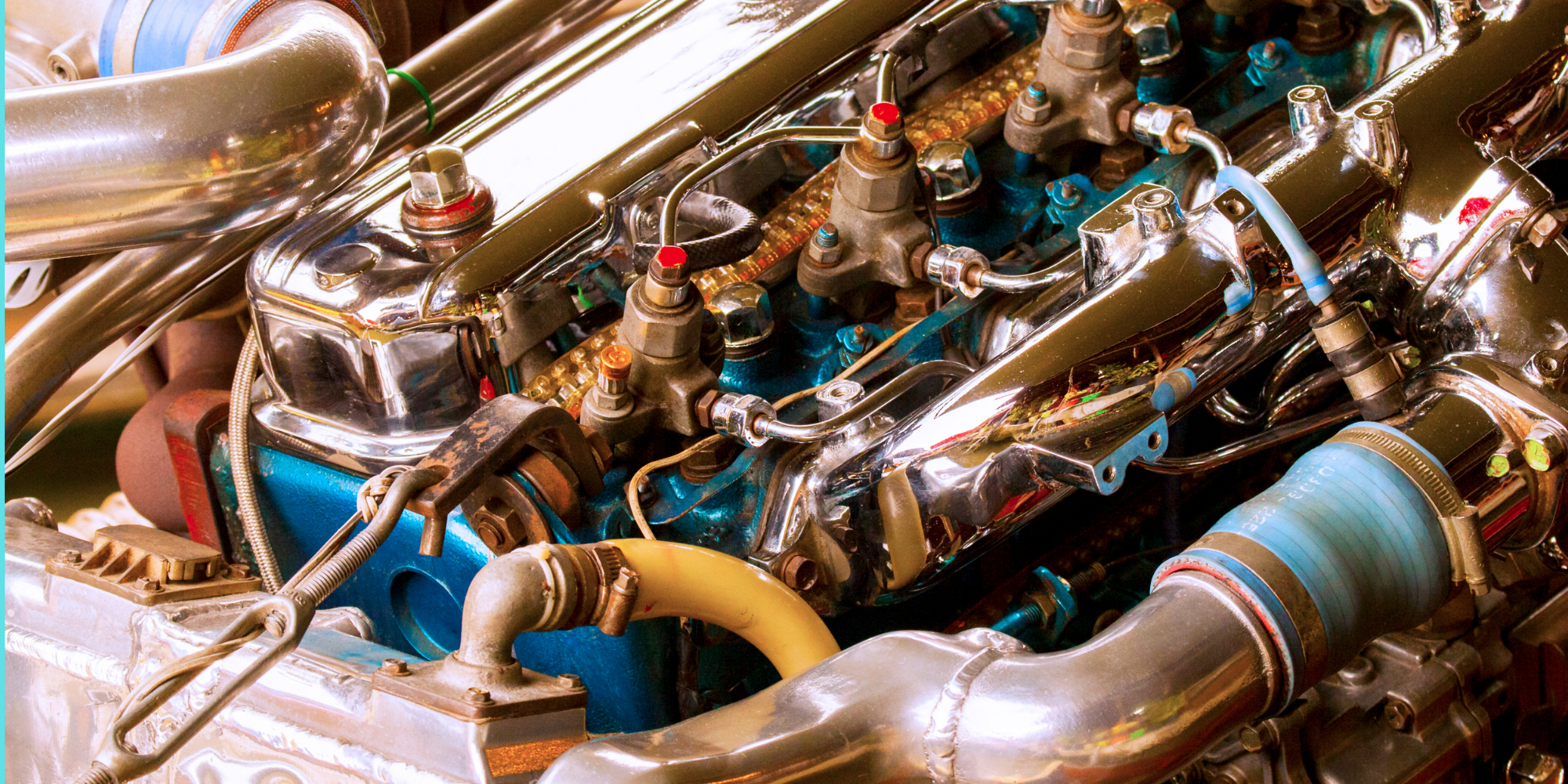

Focus on repairing or replacing damaged wood and reinforcing the overall structural integrity of the boat. This service includes fixing broken frames, planking, and keels, ensuring the boat is safe and durable for continued use on the water.

Utilize environmentally friendly methods to strip old paint, varnish, and finishes without damaging the underlying wood. After removal, apply high-quality marine coatings and varnish to protect and enhance the boat's appearance, ensuring a long-lasting and aesthetically pleasing finish

Upgrade and repair electrical systems, including wiring, controls, and dashboard elements. This service ensures all electrical components function reliably and safely, incorporating modern advancements for enhanced performance and usability.

Offer tailored carpentry services to restore or replace wooden elements such as decks, cabins, and interior panels with precision craftsmanship. This can include custom fittings, furniture, and other wooden details that maintain the vessel’s classic look while incorporating contemporary design elements if desired

By choosing Wood-Boats for boat restoration, clients ensure their treasured vessels not only maintain their classic elegance but also receive state-of-the-art upgrades that improve performance and safety. Our expert restoration services extend the life of the boat, increase its market value, and make it a pleasure to use, whether cruising leisurely or participating in boat shows. This dual focus on preserving the past and embracing the future makes our services an invaluable investment for every boat owner.

Our team consists of highly skilled artisans and technicians who specialize in the restoration of classic and luxury boats. This expertise ensures that every project is handled with the highest level of precision and care, respecting the original craftsmanship while integrating the latest restoration techniques.

We offer tailored restoration services that meet the unique needs and preferences of each client. Whether it's a full structural overhaul, custom woodwork, or a specific finish application, our approach is designed to align closely with the client’s vision and the boat’s specific requirements.

Utilizing the latest in eco-friendly restoration technology, we ensure that our processes are not only effective but also environmentally responsible. This commitment not only protects the environment but also ensures that the boat's materials are treated with the most gentle and sustainable methods available.

From the initial assessment and detailed planning phases to the final touches, our team manages every aspect of the restoration process. Clients receive regular updates and have a clear point of contact, making the restoration journey seamless and stress-free

A short description of your company’s role in the success of the project.

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

Blog post excerpt [1-2 lines]. This text is automatically pulled from your existing blog post.

Receive our latest blog posts directly in your inbox!